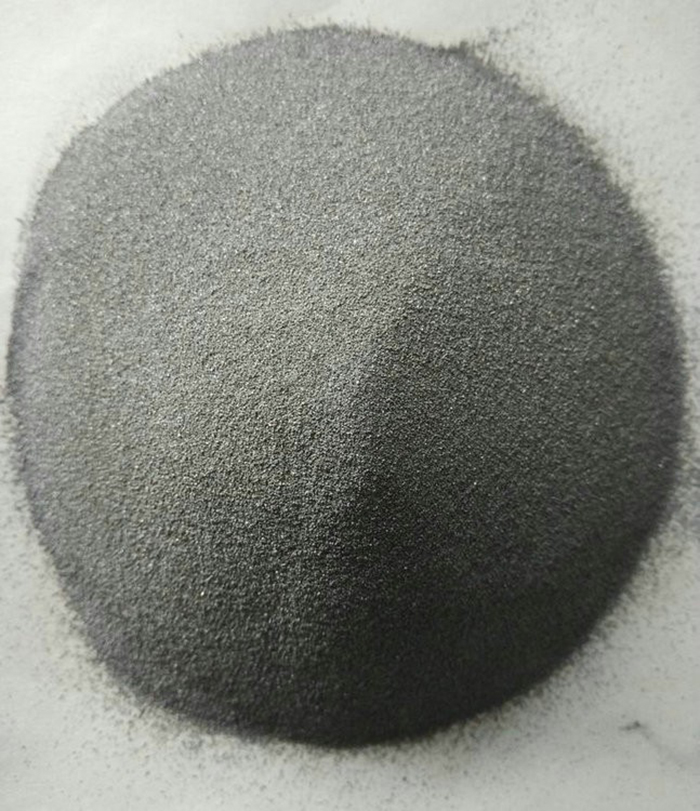

Water atomized iron powder refers to the process of using high-pressure atomized water to beat high-temperature iron into fine mist like powder through a specially designed nozzle, and then forming steel powder through processes such as sorting, dehydration, drying, reduction, crushing, screening, batching, and packaging. At present, when water atomized iron powder is separated from water, it still contains a large amount of water. If it is directly dried, it will greatly increase the drying cost. Therefore, dehydration treatment is required after sorting. The existing dehydration method is to remove the water mixed in water atomized iron powder through a drum screen or a vibrating screen. Due to the small particle size of water atomized iron powder, the sieve holes of the rolling screen or vibrating screen are difficult to meet the requirements, resulting in a large amount of water atomized iron powder loss, product waste, and poor filtration effect; Moreover, the flow-ability of water atomized iron powder mixed with water is poor, and it is easy to remain on the rolling screen or vibrating screen, affecting production continuity.

|

STANDARD OF ATOMIZED IRON POWDER |

2 |

|||||||||||

|

USES |

GRADE |

CHEMICAL(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Ni |

Mo |

Cu |

H2-loss |

insoluble matter |

TFe |

||

|

PURE IRON POWDER |

HAP100.28 |

≤0.01 |

≤0.05 |

≤0.15 |

≤0.02 |

≤0.015 |

|

|

|

≤0.15 |

≤0.15 |

≥99 |

|

HAP100.30 |

≤0.01 |

≤0.05 |

≤0.15 |

≤0.02 |

≤0.015 |

|

|

|

≤0.15 |

≤0.15 |

≥99 |

|

|

HAP100.30H |

≤0.01 |

≤0.035 |

≤0.15 |

≤0.02 |

≤0.015 |

|

|

|

≤0.12 |

≤0.15 |

≥99.4 |

|

|

Distalloy |

HAK-1 |

≤0.01 |

≤0.05 |

≤0.15 |

≤0.02 |

≤0.015 |

1.70-2.00 |

0.45-0.55 |

1.40-1.60 |

≤0.15 |

≤0.15 |

|

|

easy cutting |

HAQ100 |

≤0.01 |

≤0.05 |

0.15-0.35 |

≤0.02 |

0.2-0.45 |

|

|

|

≤0.15 |

≤0.15 |

|

|

welding |

HS100.28 |

≤0.01 |

≤0.05 |

≤0.15 |

≤0.02 |

≤0.015 |

|

|

|

≤0.15 |

≤0.15 |

≥99 |

|

HT40.30 |

≤0.01 |

≤0.1 |

≤0.15 |

≤0.02 |

≤0.015 |

|

|

|

≤0.5 |

-- |

≥98.5 |

|

|

HT40.37 |

≤0.01 |

≤0.1 |

≤0.15 |

≤0.02 |

≤0.015 |

|

|

|

≤0.5 |

-- |

≥98.5 |

|

|

|

|

|||||||||||

|

USES |

Grade |

apparent density |

Flow S/50g |

compressibility |

granule distribution(μm)(%) |

|||||||

|

|

180~150 |

150~100 |

100~75 |

75~45 |

<45 |

|||||||

|

pure iron powder |

HAP100.28 |

2.80±0.10 |

≤30 |

≥7.06 |

|

≤10 |

10~25 |

20~40 |

20~40 |

20~35 |

||

|

HAP100.30 |

3.00±0.10 |

≤30 |

≥7.06 |

|

≤10 |

10~25 |

20~40 |

20~40 |

20~35 |

|||

|

HAP100.30H |

3.00±0.10 |

≤30 |

≥7.10 |

|

≤10 |

10~25 |

20~40 |

20~40 |

20~35 |

|||

|

distalloy |

HAK-1 |

3.00±0.10 |

≤30 |

≥7.06 |

|

≤10 |

10~25 |

20~40 |

20~40 |

20~35 |

||

|

easy cutting |

HAQ100 |

3.00±0.10 |

≤30 |

≥6.70(500Mpa) |

|

≤10 |

10~25 |

20~40 |

20~40 |

20~35 |

||

|

Welding |

HS100.28 |

2.80±0.10 |

|

|

customized |

|||||||

|

HT40.30 |

3.00±0.10 |

-- |

-- |

|

|

|

>425 |

425~250 |

250~180 margin |

<180 |

||

|

HT40.37 |

3.70±0.10 |

-- |

-- |

|

|

|

>425 |

425~250 |

250~180 margin |

<180 |

||

Contact person: Mr. Zheng

Tel: 0531-76470529/13326345131

E-mail :admin@dadaalloy.com

Address: Lixin Town, Gangcheng District, Jinan City, Shandong Province